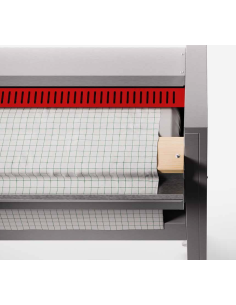

Ironing Machine with Roller cm 140 - Ø cm 18 - cm 161 x 39.5 x 107 h

DL-GR-STI140

DL-GR-STI140

€3,500.00

€3,500.00 Senza tasse

€4,270.00 Con tasse

Tax excluded

Shipping times: from 3 days to 15 working days

Ironing Machine with Roller cm 140 - Model STI140 - Automatic concave movement - Productivity kg 34 - Variable speed drive - Length cm 140 - Diameter cm 18 - Power kW 5.58 - Three-phase - Dimensions cm 161 x 39.5 x 107 h

Options

+ ACCESSORIES

| Ironing machine | STI140 |

| Dimensions product | Cm 161 x 39.5 x 107 h |

| Dimensions packaging | Cm 172 x 53 x 131 h |

| Net weight / Gross | Kg 105/116 |

| Warranty | 12 months |

| Standard | CE |

| Origin | Italy |

| TECHNICAL DATA | |

|---|---|

| Roller diameter | mm 180 |

| Roller length | mm 1400 |

| Productivity kg/h with RH% 10÷15% | 34 |

| Roller speed | Variable (mt/min) 1.3 -3.0 |

| Electronic Control | FOX |

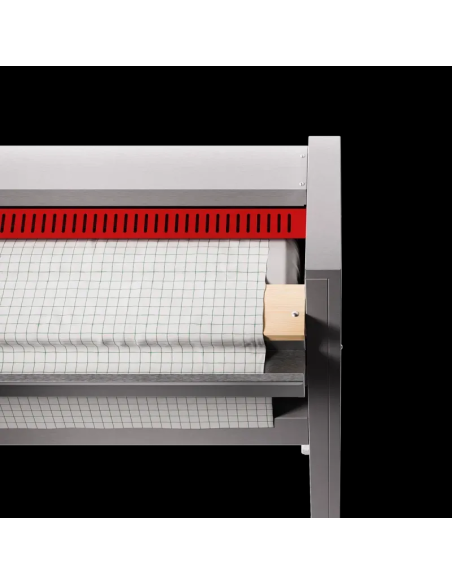

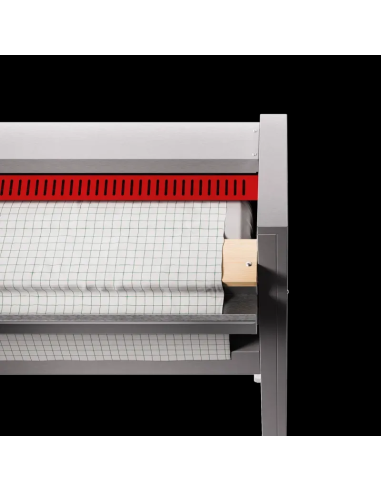

| External roller covering | Cotton cloth |

| Ironing plate | 0.252 m2 |

| Conca movement | Automatic |

| Thrust adjustment | Standard |

| ELECTRICAL DATA | |

|---|---|

| Power supply | Three-phase V380-415/3/50H |

| Power of heating | kW 5.4 |

| Power roller motor | kW 0.03 |

| Power basin motor | Kw 0.05 |

| Power total | Kw 5.58 |

| Noise level | 60 dB |

| GENERAL FEATURES | |

|---|---|

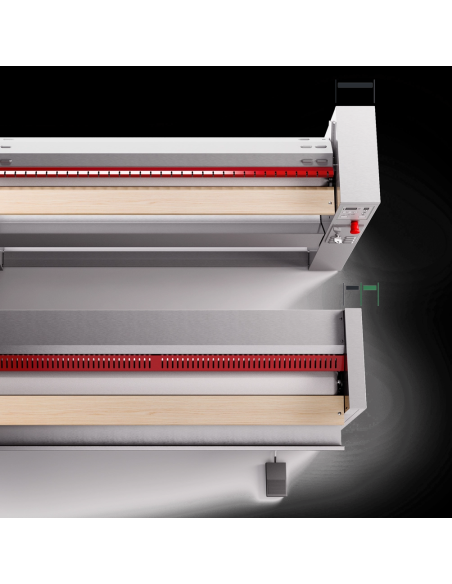

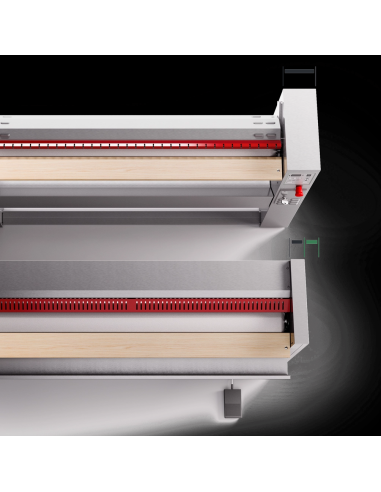

| Self-supporting structure made of gray plasticized sheet metal with side shoulders of reduced size to benefit the width of the roller useful for ironing operations | |

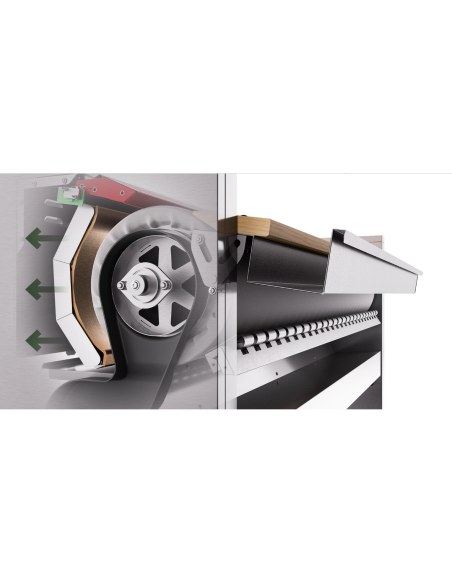

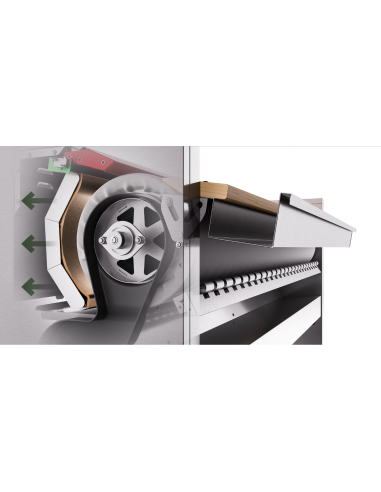

| Automatic conca movement through new patented maintenance-free and self-adjusting system | |

| Pushing elements positioned behind the conca for uniformity of ironing quality along the entire roller | |

| Conca made of aluminum treated with deep anodizing to ensure long life and energy savings | |

| Heating elements positioned inside the aluminum ironing basin for excellent heat transmission | |

| Thermal insulation with thick ceramic wool | |

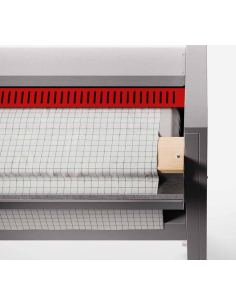

| Roller supported by bearings and padded with triple layer of steel wool, cotton molleton and cotton outer cloth (Optional with Aramid Fabric Cloth) | |

| Single-front use with the possibility of wall-mounting the ironer side-by-side | |

| Wooden axle for easy introduction of linen with adjustable angle so as to adapt to the height of the operator | |

| Large upper portion of the roller available to the operator to achieve an introduction band effect particularly useful in the case of large garments | |

| Finger-saving device to protect the operator in case of wrong maneuvers with forced air cooling system | |

| Fox electronic control with temperature control with electronic thermostat, roller rotation speed variator, selection of the thrust of the aluminum basin towards the roller | |

| Control panel placed in such a way that parameters can be managed easily with one finger and without moving from the workstation | |

| Safety thermostat to prevent unwanted overheating with manual reset | |

| Movable foot pedal for controlling the movement of the trough (opening/closing) if thicker-than-normal garments are to be introduced occasionally | |

| Automatic device for moving the basin away from the roller in the event of a power failure that secures the machine and immediately allows the garment that was being ironed to be removed |

100 Items