Mantuator - Production Kg/h 18 max 100 - 61.3 x 108 x 146 h

V-MR-SMARTY16TTI

V-MR-SMARTY16TTI

Product to quote

€0.00

€0.00 Senza tasse

€0.00 Con tasse

Tax excluded

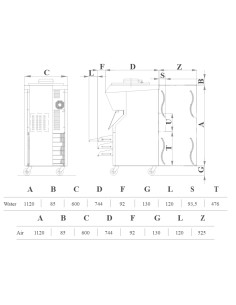

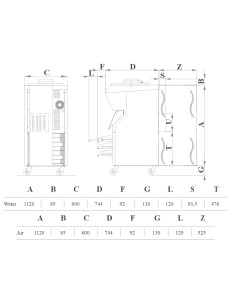

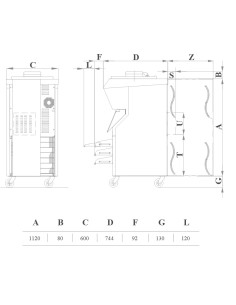

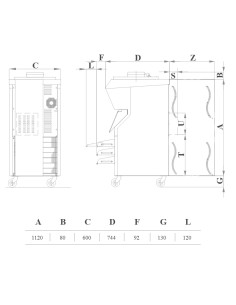

Multi-functional electronic handler - Model SMARTYTTI - Production per cycle Kg blend 3 max 16.5 - Oral production Kg 18 max 100 - Water-condensed - Dimensions cm 61.3 x 108 x 146 h

| PRODUCT INFORMATION | |

|---|---|

| Multifunctional Mantua | SMARTYTTI |

| Dimensions | cm 61.3 x 108 x 146 h |

| Weight | KG 420 |

| Warranty | 12 months |

| Norma | CE |

| TECHNICAL DATA | |

|---|---|

| Capacity | kg/h 18-100 / Blend cycle 3 max 16.5 kg |

| Power | Kw 20.3 |

| Power supply | 400V - 3 - 50Hz |

| Condensation | Water |

| GENERAL FEATURES | |

|---|---|

| Through the technological solutions it expresses it is able to meet the needs of the most advanced and complex processes in the field of ice cream, allowing to work in a separate way (single recipe) or from a white base, with the jointing of one or more shepherds.Each detail has been evaluated, designed, manufactured and tested, taking into account the needs of the many working methodologies present in the artisan ice cream industry. | |

| The relationship between diameter and depth has allowed to realize a “technological pot” with a very wide base, to optimize the thermal exchange on the bottom without burning or ruining the mixture inside, even if delicate or in minimum quantities | |

| Speed, precision in temperature and reduction of thermal inertia is a difficult result to obtain, especially with dense mixtures, but with Smarty it is possible thanks to: – Partialized resistances with dry and electronic management with PLC, which allows resistors to operate individually, alternatively and simultaneously.– Three probes for precise temperature control and reduction of thermal inertia.–Possibility to cook evenly from the minimum of 20% to the maximum of 100% of the capacity of the tank.– Possibility to cook up to 98°C. | |

| The agitator is another important point of the heating part, equipped with patented counter agitator, completely disassembled quickly and easily, to ensure a fast dispersion and solubility of solid ingredients in liquid ones. | |

| Double lid with servo-assisted opening system with hydraulic pistons for easy introduction of the ingredients even during the working phase already begun, without having to stop the machine, in full compliance with the certified safety standards CE | |

| External faucet with passage of the mixture direct to the bath and contemporary independence of the heating part from that of cooling:– Variable progression opening system –Simple and fast to disassemble,with the possibility of sanitizing each surface in contact with the product–Anti-injury safety system with certification CE–Realized completely in 18/10 stainless steel for a duration over time and easy sanitization in dishwasher, without deterioriating with use–Rotation up to 180° for the use also independent of the heating tank, from the cooling cylinder | |

| Possibility to perform cooking and/or heating with relative extraction, of the same independently, from the maintenance cylinder.Antisprust system in the travase phase and start of the mantecatore with liquid mixtures.Support for extraction of hot machining independently from the cooling cylinder. | |

| Wide hopper with patented protection grille, located on the handler door, to facilitate the load of the cylinder in the case of use of the maintenance part independently from the heating part | |

| The new system revolutionizes the quality standards of discontinuous mantle, allowing to obtain a creamy and dry ice cream with built-in air that can reach 40% of the mix weight, preserving it in the finished ice cream and giving the same greater cream and softness | |

| Speed changer of agitator rotation with range from 7 to 70 Hertz.Through the PLC and the inverter the new guarantees an optimal maintenance in relation to the characteristics of the mixture, ingredients and balance, and the quantities produced.Absolute novelty is the ability to select the automatic management of ice cream extraction, preserving dry ice cream from the beginning to the end of the extraction | |

| The cubic centimeters of the cylinder are distributed in a minucious relationship between diameter and depth of the cylinder, studied and tested to ensure the synthesis between cooling, freezing speed and micro-crystallization of water, and optimization of the incorporation of air. | |

| The particular design, the helical inclination with variable convergence of the blades, the high and cienza scrapers are only some of the details that erenziano the new agitator of the series , allowing to obtain a perfect maintainance thanks to the systematic and homogeneous handling of the ice cream on the whole surface of the cylinder, avoiding the excessive freezing of ice cream on the blades or at the center of the cylinder (cross effect) | |

| Direct expansion system of the refrigerant gas on the maintenance cylinder with progressively variable diameter hollow spiral, to optimize the refrigeration output, on the entire cylinder surface | |

| The consistency control takes place through the measurement of the couple of the agitator in newton meter, the temperature of the gas and that of the ice cream inside the cylinder.This technological solution allows you to obtain the desired consistency regardless of the recipe | |

| 33 Programmes: 11 heating programmes for ice cream mixtures, 11 ice cream maintenance programmes, 2 granite and fruit cream programmes, 6 controlled extraction programmes for ice-cream,2 specific mixing and agitation programmes for single tank, 1 +4°C cooling programme for ice-cream mixtures |